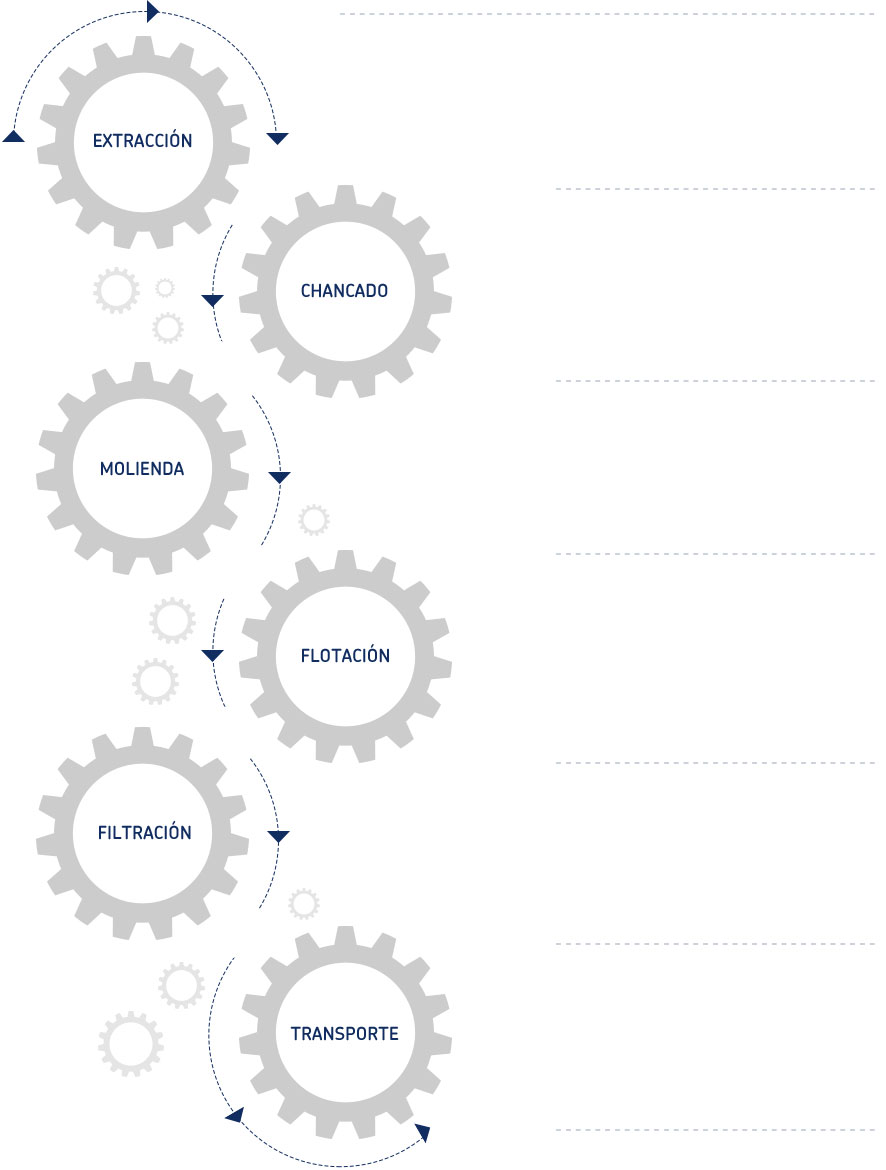

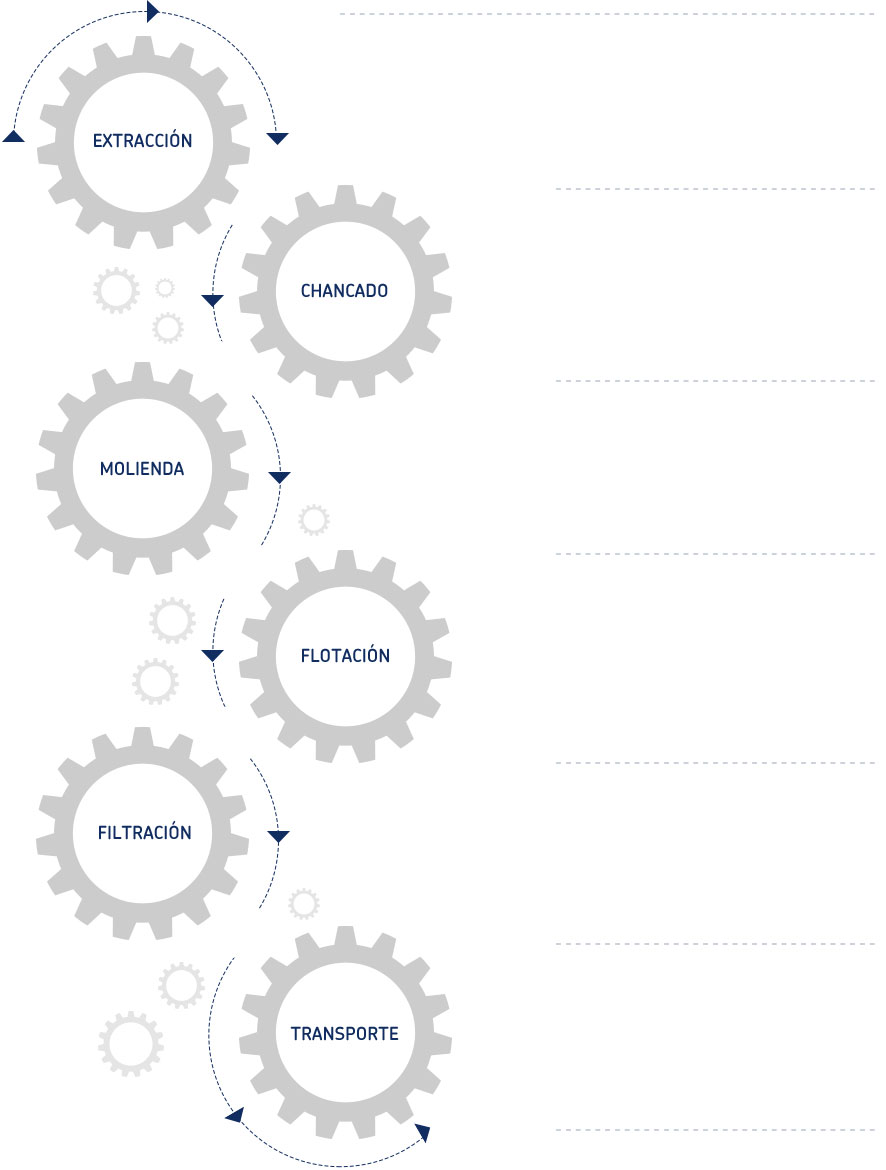

Extracción

The ore we extract is

near the surface

Chancado

We reduce the mined material

to a maximum of 18 cm

Molienda

We reduce ground rock to

0.18 mm at the concentrator plant

Flotación

We separate copper sulphides

from molybdenum and other elements

Filtración

We filter copper concentrate and take

the resulting product to the warehouse

Transporte

We transport the copper concentrate

to the Port of Matarani by trucks and railway, from where it is exported.